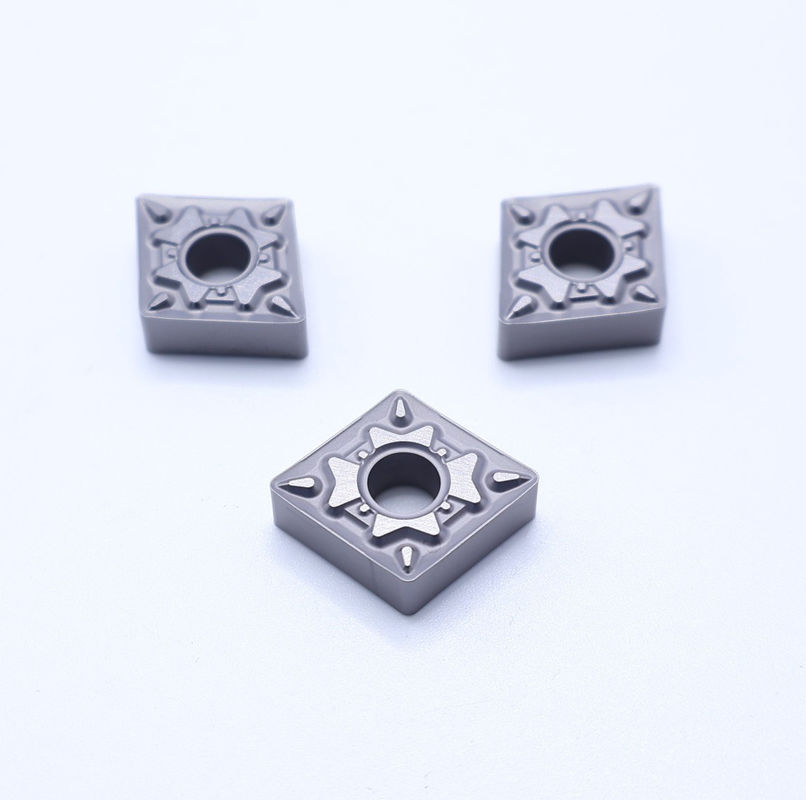

HRA92.5 Hardness Cermet Insert Turning Tools CNMG120408-FQ MC2010

Premium Cermet Cutting Tools

Metcera Grade Specifications

Coating Properties by Grade:

| Grade |

Color |

Coating Hardness (HV) |

Antioxidant Temp. (°C) |

Frictional Coefficient |

Coating Thickness (µm) |

Recommendation |

| PV1120 |

Golden |

3500 |

900 |

0.3 |

2-2.5 |

Steel, Alloy HRC<50 Tempered Steel |

| PV2110 |

|

|

|

|

|

|

| PV3115 |

|

|

|

|

|

|

| PV1220 |

Grey-black |

3500 |

900 |

0.3 |

2-2.5 |

Steel Machining |

| PV2210 |

|

|

|

|

|

|

| PV3212 |

|

|

|

|

|

|

| PV1320 |

Bronze |

4200 |

1000 |

0.3 |

2-2.5 |

Stainless Steel, Steel HRC<50 Tempered Steel |

| PV2310 |

|

|

|

|

|

|

| PV3315 |

|

|

|

|

|

|

Base Material Properties:

| Grade |

Density |

Base Material Hardness HV30 |

HRA |

Bending Strength (MPa) |

| MC1020 |

6.5 |

1650 |

93.0 |

1800 |

| MC2010 |

6.8 |

1550 |

92.4 |

2300 |

| MC3015 |

6.95 |

1520 |

92.0 |

2500 |

Advanced Cermet Technology

Ti(CN) based cermet is a cutting-edge material that combines the toughness, high thermal conductivity, and excellent heat stability of metals with the high hardness, superior red hardness, and corrosion resistance of ceramics. These unique physical and chemical properties make cermet an ideal material for manufacturing specialized cutting tools, wear parts, and corrosion-resistant components.

Why Choose Our Cermet Tools

- 30 years of specialized experience in cermet cutting tools

- Performance equivalent to world-class brands

- Grade compatibility with TN60, NX2525, CT3000, T1200A, CN2000, NS530

- Comprehensive ODM services available

- 90-day warranty for exchange and return

- Free samples provided upon request

Frequently Asked Questions

Are you a trading company or manufacturer?

We are a manufacturer with direct production capabilities.

Do you provide samples? Are they free?

Yes, we offer free samples for evaluation.

What payment terms do you accept?

We accept T/T, Western Union, PayPal, Credit Card, and other major payment methods.

Do you provide customized product services?

Yes, we offer comprehensive customization services.

What kind of production equipment do you use?

We utilize advanced machinery including Osterwalder pressers, Agathon grinders, Nachi manipulators, and other precision equipment.

What is your lead time?

Typically 10 days after payment receipt, with flexibility based on order quantity and production scheduling.

How do you guarantee product quality?

Our company operates under ISO9001 standards with over 30 years of quality control experience and a rigorous quality management system. We provide a 90-day free replacement guarantee.

What is your packaging standard?

Standard packaging includes 10 pieces per plastic box, 50 pieces per case, and 500/1000 pieces per carton. Custom packaging is available upon request.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!